Importance of a good value flow map for SMEs

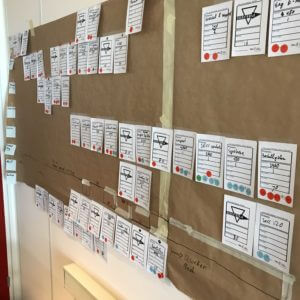

Value Stream Mapping

You want to bet your Value Stream Map in your company is not right, or worse still missing?

Let’s be realistic. Many companies that I have been visiting over the last 20 years had no or only a partial Value Flow Map. What is so exciting about that?

The source of all problems?

From small to large companies, they all have to deal with a Flow that starts with a quotation request and which of course must end with the delivery of a service or a complete product. Of course, it is difficult when you deal with many departments that all have to meet their own targets and are also very busy with the ongoing activities. So what do you do? We start at the heart of the company where the visible activities take place. Not a bad idea, of course, but whether the pain really is there is of course the question.

True or False.

Addressing the operational activities such as production and assembly departments certainly gives a good appearance and can therefore be very useful. But if attention is only focused on this, the effect can sometimes be disappointing. The simple fact: the front of a process largely determines the success for improvements! One of the reasons to focus Lean projects mainly on operational management lies in the fact that our accounting and planning systems focus on measurable items such as manhours and materials. These systems mainly looking at the visible (measured) hours and Kilos. Very useful, of course, but you will not get the basic problem or the root cause over the table!

CLEAN ORDER.

Strikingly enough we encounter the problem at many companies that at the front is not clear at all what exactly has been sold under which conditions. If your margins are big enough then you can live with this, but in many cases this margin has shrunk considerably under the influence of the competition. A while ago I had an organization that had to go back to the customer 6 times to ask what the customer really required! And the longer the lead time, the more complex this process will become.

If you manage to make the process well manageable at the front, there are plenty of Lean tools on the horizon. Of course, a process from Push to Pull can be reversed, which can result in considerable time savings (standard rule at least 50% lead time reduction).

Current versus future Value Stream

A further challenge for many companies that have ever started to make its Value Stream Map (VSM) is a familiar one. It is only one! What do you mean? Well a kind of combination of a current flow and something that we are likely to achieve.

Unfortunately, that does not work, of course. The current flow of 1 process is the actual representation of how a product or service passes through the organization, based on facts. After the 7 (or 8 if you wish) Wastes have been released on this, you can start working on the Future Value Stream Map. I myself keep a period of up to 2 years to achieve this. Enough for a vista, but also realistic when it comes to practical feasibility.

Let yourself be coached

Of course, the biggest pitfall remains the downplay of possible improvement options. The well-known knockdown arguments and excuses of people who cannot or do not want to change are always present. Internal process improvers often see themselves confronted with this or are themselves already demotivated due to this. My advice is to use an external expert for this part.

With 20 years of experience we have already seen all the excuses. In all cases, we will work out the current and future value stream map in 2 days including the plan to get there together with your core team!

You want to catch up? I like to come along because: Good can always become better!

Nieuws & Blogs

- Een dagstart alleen is niet voldoende 26 mei 2023

- Ook LMP groeit door! 3 mei 2023

- Checklist voor ondernemers 19 juli 2021

- Top-Down vs Bottum-Up 22 december 2020

- Top-Down vs Bottum-Up 22 december 2020

News & Blogs

- Een dagstart alleen is niet voldoende 26 mei 2023

- Ook LMP groeit door! 3 mei 2023

- Checklist voor ondernemers 19 juli 2021

- Top-Down vs Bottum-Up 22 december 2020

- Top-Down vs Bottum-Up 22 december 2020